Regular Kitchen Suppression Inspections in Spring Lake are crucial for maintaining fire safety in commercial kitchens. These thorough checks assess the functionality and adherence to regulations of kitchen suppression systems, ensuring prompt fire control in cooking areas. Professionals inspect critical components like sprinkler systems, extinguishers, and gas shut-off valves, verifying proper installation, functionality, and maintenance records. Regular inspections identify potential issues, enhance operational resilience, and uphold regulatory requirements, ultimately safeguarding lives and properties.

- Understanding Kitchen Fire Safety Requirements

- The Role of a Kitchen Suppression Inspection in Spring Lake

- Key Components of a Kitchen Suppression System

- Conducting Comprehensive Fire Suppression Compliance Checks

- Post-Audit Action Plan for Enhanced Kitchen Fire Safety

Understanding Kitchen Fire Safety Requirements

The Role of a Kitchen Suppression Inspection in Spring Lake

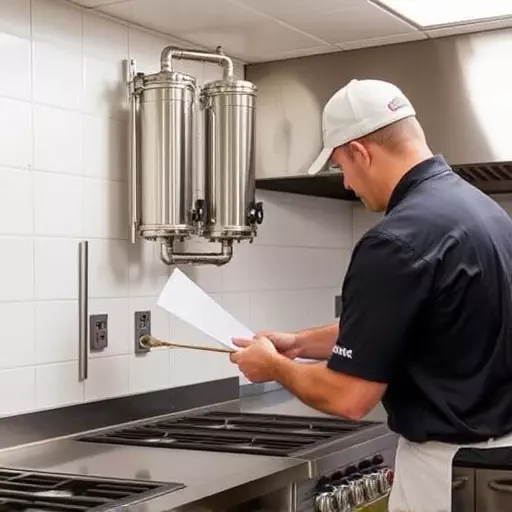

In Spring Lake, a Kitchen Suppression Inspection plays a vital role in ensuring fire safety within commercial kitchens. These comprehensive inspections delve into the functionality and compliance of kitchen suppression systems, which are critical for mitigating fires in cooking environments. During such checks, professionals meticulously assess fire suppressants, detection devices, and emergency response procedures to guarantee adherence to local fire codes and regulations.

Regular Kitchen Suppression Inspection helps identify potential hazards and ensures that life-saving equipment is operational and up-to-date. By conducting these inspections, businesses can maintain fire suppression compliance, minimize risks, and protect both their operations and the safety of their employees and customers in the event of a kitchen fire.

Key Components of a Kitchen Suppression System

A comprehensive kitchen fire safety documentation audit involves assessing critical components of a kitchen suppression system. These systems are designed to detect and suppress fires in their early stages, minimizing damage and ensuring the safety of staff and patrons. Key elements include regular inspections of fire suppression equipment, such as sprinkler systems, fire extinguishers, and gas shut-off valves. During a Kitchen Suppression Inspection Spring Lake, professionals meticulously check for proper installation, functionality, and maintenance records.

Compliance checks are essential to verify that all devices meet local fire safety codes and standards. This includes examining the integrity of sprinkler heads, testing the pressure in fire suppression pipes, and ensuring that fire extinguishers are up-to-date with regular servicing. By focusing on these aspects, businesses can maintain a robust kitchen fire safety program, enhancing their operational resilience and adherence to regulatory requirements.

Conducting Comprehensive Fire Suppression Compliance Checks

Conducting thorough fire suppression compliance checks in a kitchen setting is an essential aspect of ensuring safety and preventing potential disasters. These inspections, tailored to the specific needs of commercial kitchens, involve meticulous examination of every component within the kitchen suppression system. From sprinkler heads and control valves to fire alarms and detection devices, no detail should be overlooked. In Spring Lake, professional inspectors employ state-of-the-art equipment to test and verify the functionality and efficiency of these critical systems.

Regular Kitchen Suppression Inspection plays a pivotal role in maintaining optimal safety standards. During these checks, experts assess the system’s readiness to suppress or extinguish fires promptly, minimizing damage and protecting lives. This process includes verifying proper maintenance records, ensuring regular testing, and identifying any potential issues or deficiencies that may compromise the effectiveness of the fire suppression equipment.

Post-Audit Action Plan for Enhanced Kitchen Fire Safety